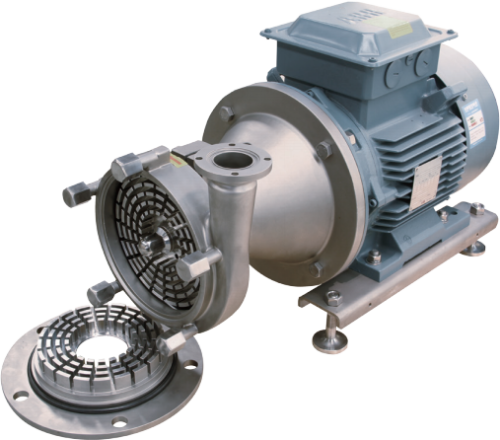

Shear homogeneous emulsification pump

|

YRP series pump is single-stage multiple and three- stage multiple homogeneous shear emulsification pump, which is customized designed and developed by our company for customers. Especially the pump cover and impeller are made by thicker stainless steel shaped with molding processing, with high hardness, good strength, smooth surface, no tiny pores. The material is thrown into the narrow |

precision gap between the stator and rotors under the high-speed rotation of centrifugal force by the rotors, outer edge of the rotor make the material extrusion, shearing, crushing, impact, tear at a higher line speed (up to 45m/s) and then from the stator groove radial direction shoot out with high- speed. Material produce two strong turbulence in the pump cavity under the action of the various forces |

between the stator and rotor during the formation of the turbulent mixture process, the multi-phase (solid, gas, liquid) medium instantly fully effective mixing, to reach the homogeneous and emulsification. The type and interval of the impeller and pump cover can be customized according to the requirements of material and working conditions, the min. Interval can be 0.2mm. |

Technical parameter

Applicable industries: Food, Beverage, Juice, Biological, Pharmaceutical, Dairy, Fructose, Wine, Vinegar, Soy sauce, Daily chemicals, Water

Working conditions: Flow rate ≤ 80 m3/h,Head ≤ 35 m,Pressure ≤ 12 bar, Temperature ≤ 180℃

Mechanical seal: Single seal or Double mechanical seal with cooling

water ( silicon carbide/ graphite, silicon carbide/ silicon carbide, carbide/ cemented carbide)

Connection: Union, Tri-clamp, Flange (ISO. DIN, SMS,IDF, RJT, GB)

Installation dimensions

|

尺寸 Size 功率 Power |

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

进口 Inlet (DN) |

出口 Outlet (DN) |

|

YRP 3752-5.5kw |

54 |

184 |

38 |

247 |

339 |

632 |

216 |

270 |

130 |

33 |

95 |

65 |

40 |

|

YRP 3752-7.5kw |

54 |

184 |

38 |

247 |

339 |

632 |

216 |

270 |

130 |

33 |

95 |

65 |

40 |

|

YRP 3752-11kw |

54 |

212 |

38 |

277 |

445 |

767 |

254 |

350 |

130 |

33 |

95 |

65 |

40 |

|

YPE 7258-11kw |

51 |

235 |

38 |

304 |

445 |

786 |

254 |

350 |

150 |

35 |

132 |

80 |

50 |

|

YPE 7258-15kw |

51 |

235 |

38 |

304 |

445 |

786 |

254 |

350 |

150 |

35 |

132 |

80 |

50 |

|

YPE 7258-18.5kw |

51 |

235 |

38 |

304 |

445 |

831 |

254 |

350 |

150 |

35 |

132 |

80 |

50 |

|

YPE 7258-22kw |

51 |

235 |

38 |

304 |

445 |

856 |

279 |

350 |

150 |

35 |

132 |

80 |

50 |

Note:

1. Dimension of C,J in this table is under Union standard connection, Clamp and Flange connection will be deviation under different situations, the exact dimensions are subject to the actual situation.

2. Dimension of F,H in this table is under general motor, Explosion- proof motor and frequency motor there will be deviation under different situations, the exact dimensions of F,H are subject to the actual situation.