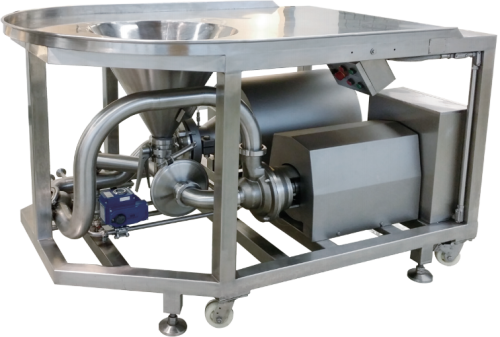

Design of high efficiency shear homogenizing emulsification mixing system

|

YRPM high efficiency homogenizing emulsification mixing system is customized designed for shearing, homogenizing, emulsification of the dry powder and wet powder. This system consist of 1 set self-priming pump, 1 set high efficiency hearing homogenizing emulsification pump, hopper platform, control unit. Auto or half- auto handing with support of packing and other transportation equipment. YRPM high efficiency homogenizing emulsification mixing |

system can mix kinds of proportional materials to be fully homogenizing products. Powder transmission through the hopper valve by self-priming pump into the high efficiency homogenizing emulsification pump. The material is thrown into the narrow precision gap between the stator and rotors under the high-speed rotation of centrifugal force by the rotors, outer edge of the rotor make the material extrusion, shearing, crushing, impact, tear at a |

Technical parameter

Applicable industries: Food, Beverage, Juice, Biological, Pharmaceutical, Dairy, Fructose, Wine, Vinegar, Soy sauce, Daily chemicals, Water treatment and so on.

Working conditions: Flow rate ≤30 m3/h, Head ≤35m, Pressure ≤ 12 bar, Temperature ≤ 180℃

Mechanical seal: Single seal or Double mechanical seal with cooling water (silicon carbide/ graphite, silicon carbide/ silicon carbide, carbide/ cemented carbide)

Connection: Union, Tri-clamp, Flange (ISO. DIN, SMS, IDF, RJT, GB)

Materials: 304(1.4301), 304L (1.4306), 316L (1.4404), EPDM, FPM, VMQ, NBR, etc.

YRPM

Compared with the traditional process, the high efficiency shearing and homogeneous emulsion system is superior.

1 Compared with the traditional mixing process

(such as: in a large mixing tank, the use of a mixer for mixing), the use of efficient shear homogeneous emulsion mixture system can save about 90% of the processing time.

2 High shear homogenization emulsion pump with high shear capacity and constant speed, it can

crush the bulk into the mass of the material, and to

ensure that each batch of materials with the same homogeneous emulsion effect.

3 The high shear rate of homogeneous emulsion

pump is very high, according to different application products, can save different raw materials (such as: processing stabilizer, can save about 12% of raw

materials).

4 High shear homogeneous emulsion system is

simple in structure and easy to maintain. It can be accessed by CIP system and is easy to be cleaned.

5 High shear homogeneous emulsion system is compact in structure and small in use, it can be easily integrated into existing production line and system.

Efficient shearing and homogeneous emulsion system configuration

|

型号 Model |

流量 Flow (m³/h) |

自吸泵功率 Self - priming pump power (kw) |

剪切泵型号 Shear pump model |

剪切泵功率 Shear pump power (kw) |

长 x 宽 x 高 Length x width x height (mm) |

|

YRPM-10 |

0~10 |

5.5~7.5 |

YRP 3752 |

7.5~15 |

1500x1050x1200 |

|

YRPM-30 |

10~30 |

7.5~11 |

YRP 7258 |

15~30 |

1800x1350x1200 |